Previously, breastfeeding mothers used to express milk manually, but now everything has changed, and special devices are available to women living in the modern world. In this article you will learn about how to properly express breast milk with a breast pump, how often to do it, and what are the benefits of this process. Should we always listen to the advice of our mothers about an “artificial” way to empty our breasts?

For new mothers, breastfeeding usually raises many questions. And one of the most pressing topics is how to express breast milk using a breast pump. First of all, they are interested in when it is necessary to express milk. Usually, the older generation intimidates inexperienced nurses with stories that if the breasts are not emptied, the milk will “burn out.” We will also answer the question of whether it is painful to express the mammary glands, and whether there is an alternative.

Why choose a mechanical breast pump

The so-called manual devices designed for expressing breast milk are divided into 2 categories - syringe and pump (there is also a variation with a pear). The latest devices are quite inconvenient to use.

Therefore, if you are thinking about purchasing a breast pump, it is better to choose the first option. Compared to a device with a pump, this model is more convenient, and compared to an electric breast pump, it is safer. The only negative is that you need to devote a lot of time to the pumping process (up to 15-20 minutes per breast).

Basic machining

This process can also be called centrifugal separation - this is one of the basic cleaning procedures that involves dividing milk into fractions of different densities. For example, skim and high-fat milk (cream) can be separated. Technically, the process is organized using the power of a separator with a rotating drum. During its operation, the installation operator monitors the following parameters of mechanical milk purification:

- Drum rotation speed.

- Rate of fat globule release.

- Density of fat and plasma.

- Viscosity.

As the density of milk plasma and fat globules increases, the rate of separation and release of the creamy mass accelerates. In turn, an increase in viscosity helps to reduce the rate of separation of fat fractions. The process of centrifugal milk purification is indirectly affected by the temperature and acidity of the milk. Acidity can change the protein mass of milk by increasing its colloidal state. As a result, the process of flakes will begin to fall out against the background of an increase in viscosity and difficulty in separation. As for the temperature effect, its increase reduces the level of viscosity and slows down the process of transition of the fatty thick mass into a liquid state. Therefore, before separation, it is recommended to heat the milk to 35–45 °C. Increasing the temperature will also ensure a more efficient degreasing process.

When is it necessary to pump?

Of course, it is best to put your baby to the breast on demand, but this is not always possible. Therefore, there are several situations when expressing mother's breast milk with a breast pump is justified. These include:

- When the baby is too small and is not able to suck the entire volume of milk from the breast. To avoid painful sensations or hardening of the mammary glands (which can lead to serious consequences), it is recommended to express.

- It is too difficult for the baby to get the treat, so to make it stand out better, you can stimulate this process a little by pumping.

- If you can’t feed your baby (for example, if mother and baby are in separate rooms), then expressing with a breast pump will help you maintain lactation and not lose such a healthy treat for your baby.

- Many babies do not drink milk well during teething. You can try pumping and spoon feeding your baby. But under no circumstances give treats from a baby bottle, as there is a chance that the baby will refuse the breast.

- If the mother goes to work and the child is not yet 9-12 months old. In this case, you can freeze the expressed milk product. And, for example, the baby’s grandmother or father will be able to feed him from a bottle.

In the latter case, we recommend taking care of your milk supply. You can express and freeze it in separate containers. As a rule, mother's milk product can be stored in the freezer for 3 to 6 months.

General cleaning technology

All processing operations are carried out under special conditions that meet technical and sanitary requirements. The standards applied to the organization of the work of food enterprises are taken as a basis. On dairy farms, both individual technological processes for processing raw materials and complex preparation of the product can be carried out.

The main cleaning methods today are implemented using milk separators and centrifuges with pasteurizers. At a minimum, this equipment allows you to remove milk plasma mucus, mechanical impurities and dirt particles. Finer filtration also gives a disinfection effect by destroying harmful bacteria. Methods for purifying milk through thermal and biological effects are also being developed. In such processing systems, the physicochemical properties of milk are modified, the content of surfactants (proteins, phospholipids, fat globules and acids) is optimized and surface tension is reduced.

How often should you pump?

Of course, every woman’s body is unique, as are the needs of babies. However, there are a number of general recommendations regarding pumping frequency:

- If you are afraid of losing milk after childbirth and there is no way to feed your baby regularly, then it is best to stick to this regimen. Empty your breasts for the first time within 6 hours of giving birth (don't be alarmed if you only get a few drops of yellow colostrum). After this, try to express at least once every 2-3 hours. Establishing the night process will be a huge plus.

- If your baby cannot breastfeed for some time, try to stick to the usual schedule. That is, express at exactly the same intervals as you fed the baby.

- If after feeding your baby you feel that your breasts are full and “heavy,” we advise you to express after each feeding until complete relief. This must be done on the first day of alarming symptoms, otherwise, if you do not take the problem seriously, you can get lactostasis.

Remember that if it is not possible to empty your breasts completely, pumping for 5 minutes is better than not pumping at all. Even such a short stimulation of the mammary glands gives the mother’s body a request to increase the production of breast milk.

Cooling modes

The properties of milk, and in particular its bacteriological characteristics, will largely depend on the temperature of its further storage. If you leave the product unrefrigerated, then after 10 hours its acidity will increase almost 3 times, and at the same time the number of unwanted bacteria will sharply increase. For optimal storage from the point of view of favorable microflora, long-term storage in production requires maintaining a regime of 12 ° C. Strong cooling is also not recommended, since it is also detrimental to beneficial microorganisms. Again, a milk cooler with control sensors and an automatic temperature control system, which takes into account several physical and chemical properties of milk, comes to the rescue. Such equipment can contain from 100 to 1000 liters at a time, depending on the model and production needs. The choice of specific cooling tactics will depend on the holding time, but short periods at various stages of milk purification and processing usually require maintaining 4-6 ºC.

How long can milk be stored?

Many mothers are interested in questions about how often they can express milk using a breast pump, and how long baby treats can be out of the freezer. If we are talking about a natural product, then there is no need for unnecessary worries. Breast milk has antibacterial and anti-infective properties, so it can be stored:

- about 8 hours without refrigeration at room temperature;

- in the refrigerator 7-8 days.

There is an opinion that several servings of expressed treats for a baby cannot be mixed. But this myth has nothing to do with reality. The main thing is to follow a simple rule: before mixing them together, cool the last portion to the same temperature as the previous one. We also pay attention to this point: breast milk will always separate (after all, it contains both milk fat and other lighter substances). Therefore, this is not at all an indicator of its freshness and quality.

Delivery of raw milk to production

The movement of milk between departments on the farm or its delivery by transport to the processing plant is carried out in special containers or tanks with refrigerators. According to the requirements, the internal surfaces of containers and reservoirs must be made of stainless steel or aluminum. External surfaces are finished with heat-insulating material. During the transfer process, it is important to maintain optimal temperature conditions for raw milk. So, the average temperature is 4-6 °C. The raw materials can be kept in this state for no more than 10 hours. If longer transportation is planned, then a special milk cooler is initially used - equipment in the form of a tank, which immediately after milking lowers the temperature of the liquid product from 35 to 4 °C. At the same time, pathogenic elements of the composition are removed and beneficial qualities are preserved.

How to get your milk flowing

As you know, it is difficult for babies to suck milk, so it is not surprising that proper pumping takes a lot of time. To speed up the process of expressing with a breast pump, experts recommend moving the body forward a little. But besides this, there are other recommendations:

- If you have not yet established lactation and your baby is eating colostrum, you can drink a glass of warm still water. Warm drinks help improve colostrum flow. It will also be useful to take a warm shower or do a light warming chest massage. By the way, the last manipulation is especially recommended for women with “heavy” breasts in order to prevent the development of lactostasis.

- Looking at photographs of the child also has a good effect. This also stimulates the flow of breast milk.

- You can apply a warm towel to your chest.

- Additionally, you can stimulate your nipples. Hold them between two fingers and gently roll them several times.

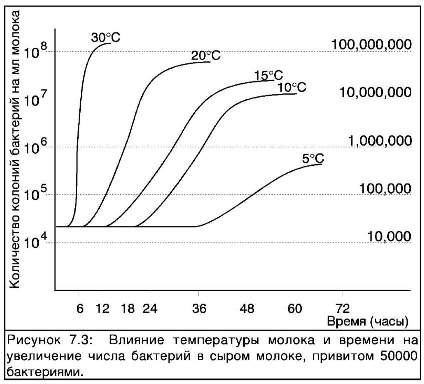

Bacteria are a big problem in dairy production

Bacteria in milk feel like “fish in water”, multiplying quickly, as can be seen in Table 1. The main source of pollution is the external environment, dust, skin particles, etc.

To prevent mass spoilage of products, it is necessary to keep cows clean, taking care of their hygiene, carefully treat the udder before milking, work in special clothing, process and disinfect milking machines, strainers, etc., promptly replace milk filter

.

In this case, bacterial contamination can be minimized, but it is almost impossible to prevent it completely.

Recommendations for pumping

Often nurses are interested in how to properly express breast milk with a breast pump. It's no secret that this process is difficult for many women.

- First you need to wash your hands and breasts.

- Before using the device, carefully read the instructions. The duration of the process of expressing breasts using a breast pump depends on the volume of milk in the mammary glands. Typically it takes 10 to 15 minutes for each breast. If breast milk stops flowing before this time, stimulate this process artificially by continuing to “squeeze” droplets for 2-3 minutes. By the way, experts believe that expressing two breasts has a better effect on the lactation process. They recommend that women who are concerned about this issue express the second breast while the baby drinks a treat from the first.

- Many mothers, both at the beginning and during lactation, develop cracks in their nipples and it turns out that their irritation brings additional discomfort. When using mechanical devices, it is worth lubricating them with vegetable oil.

- To ensure that the breast pump breast shield adheres better to the breast skin, it is recommended to moisten it with a towel.

- It is equally important to choose the correct funnel size. Do not forget that in the process of properly expressing milk using a breast pump, the nipple should not be squeezed.

The funnel is selected correctly if the nipple areola does not fall into the funnel tunnel, and also if the breast remains evenly empty on all sides after pumping. Please note that if a woman has large mammary glands and nipples, then it is better for her to choose the largest breast shield.

Learning to use the Avent breast pump correctly

We have selected a video for you to better familiarize yourself with the process of expressing breast milk with a manual breast pump. You can also see in the video about the features of the Avent device.

“Processing milk at home”

Milk purification aims to remove visible mechanical impurities (particles of feed, bedding, hairs, etc.) by straining the milk when draining. As a strainer, you can use cotton filters, flannel, gauze folded in three or four layers, mesh made of synthetic fabrics (lavsan, nylon, etc.). It is more convenient to purify milk using a special sieve - a strainer. Cooling.In order to preserve milk, it must be cooled as quickly as possible after milking. At home, in the summer, milk is cooled in glaciers or cellars, using prepared ice, as well as in cold water (well, spring).

The best way to preserve milk is to cool it in home refrigerators. Milk cooled to +10° C can be stored for up to 24 hours, and at +5° C for up to 36 hours.

For long-term storage in winter, as well as in the presence of low-temperature refrigerators, milk can be frozen. To preserve the structure of milk, a layered method is recommended for freezing. Milk is poured into a special container (baking trays) in a layer of 2-3 cm, after it freezes, a new layer is poured, etc. Frozen milk is stored at low temperatures.

Pasteurization.

The main changes in milk after milking occur under the influence of microflora, which causes its souring and the appearance of various defects that are dangerous to human health. Compliance with sanitary and hygienic rules for obtaining milk significantly reduces its bacterial contamination.

To combat microflora, milk is neutralized using high temperature (pasteurization, boiling, sterilization). Pasteurization destroys 99% of microorganisms, with the exception of spores, boiling destroys some of the spores, and sterilization destroys all spores.

When heated, gases dissolved in it evaporate from milk, proteins (albumin and globulins) coagulate and precipitate, enzymes are destroyed, some mineral salts precipitate, etc. Heating to a temperature of 80 ° C and above gives milk a special taste and aroma. . When boiling, these changes intensify, valuable substances are lost within 15-20%, so there is no need to boil milk, especially pasteurized milk, without special need.

At home, milk can be subjected to long-term pasteurization at a temperature of 63-65 ° C for 20-30 minutes, and then cooled. For the purpose of pasteurization, it is better to place milk in water that has been preheated to a boil. With this pasteurization mode, minimal changes in quality are observed in milk. You can pasteurize milk by heating to 72-74°C with holding for 30-60 seconds or up to 85-87°C without holding. If pasteurized (boiled) milk is contaminated with microflora, it spoils faster than raw milk and becomes bitter.

Preparing baked milk.

Boil the milk, pour into a lined clay dish or cast iron and place in the oven or oven for 1.5-2 hours. The resulting foam from fat and proteins should be periodically immersed in milk. When the milk acquires the appropriate creamy color, the melting process is stopped, then the milk is cooled.

Separation.

Milk is separated to obtain cream of any fat content. For home milk processing, the industry produces small separators with a capacity of 30 to 100 liters per hour with a manual electric drive (Saturn, Volga, Ural, Plava, etc.). It is recommended to install them in a heated room on the edge of a stable table or on a special stand vertically without distortions (use a plumb line and a level). Assembly, disassembly and maintenance of the separator are carried out in accordance with the instructions supplied by the manufacturer when it was sold.

Strained and fresh milk are separated, preferably fresh milk; cold milk must be heated to 30-35° C. Pasteurized or boiled milk is processed much worse, and large fat losses are observed. Gauze (2-3 layers) or other acceptable fabric (lavsan, nylon) is first tied to the separator receiver, through which the milk is filtered while filling it. Then slowly and smoothly, gradually increasing the speed, rotate the separator handle to 60-65 rpm. The electric separator is connected to the network. When it reaches the required number of revolutions (you will know this when the bell stops giving signals), the receiver tap is opened, and the milk begins to flow into the separation drum. To ensure the process is continuous, milk is periodically poured into the receiver. The fat content of the cream is adjusted by turning the butter screw, which has a square hole. When you turn it to the right, it screws in and the fat content of the cream increases, and vice versa.

At the end of separation, up to 1 liter of skim milk (skim milk) is poured into the receiver and, without rotating (or turning off) the device, wait until the skim milk flows out of the cream horn. This means that all the milk fat has been removed from the drum and the receiver tap should be turned off. At the end of skimming the milk, the dishes and the separator drum are disassembled, washed with cold water, warm soda solution (0.5%) and clean water. The separator parts are laid out on a table to dry. The rubber ring is washed in clean water and dried. Plastic parts of the separator cannot be stored at sub-zero temperatures; they become brittle; to avoid darkening, it is not recommended to dry them near an oven or in bright sunlight.

The milk is not sufficiently separated (skimmed) if it has a low temperature or is poorly cleared of mechanical impurities, as well as if the drum is not assembled correctly, its nut is loosely tightened or it is set low (the cream partially ends up in the return stream), the drain screw is not adjusted or its hole is clogged . Milk or skim milk flows out of the separator if the drum nut is poorly secured, the rubber ring is damaged, the drum is low (the skim milk gets under the horn), the ring or float is not installed correctly, or the float chamber tube is clogged. The separator trembles, and extraneous noise occurs in it when it is poorly secured to the table, or when the rotation transmission system wears out.

The performance of the separator decreases when the float chamber tube is clogged, the receiver tap is not opened sufficiently, the milk sours (the spaces between the plates become clogged), or the lubricating oil is contaminated.

Source: Iikc-apk.kuban.ru

How to care for a breast pump during lactation

After purchasing the device, it must be sterilized for 5 minutes in a pan of boiling water or a double boiler. If you have a special sterilizer for bottles, then there is no problem at all.

Every time you finish expressing milk, you need to wash your breast pump. All parts of the device that have contact with the skin of the breast and the milk itself must be thoroughly washed with laundry soap and hot water. Then wait until the parts of the breast pump dry on their own and reassemble the unit.

Expressing with a breast pump is an indispensable manipulation to avoid lactostasis. It may also be justified in some cases that we have described. But still, the best stimulator of your lactation is not a modern manual or electric device, but your child. Apply it to your chest as needed. And if you have decreased breast milk production, practice night feedings on a regular basis.

Separators for milk purification

The operations of separation of milk fractions and purification discussed above are performed on special separators. As a rule, these are electric machines that have a built-in motor, a collector, a bowl for loading milk and a centrifuge. On medium-sized farms, devices with a capacity of up to 50-70 l/h are widely used. In this case, the drum rotation speed can reach 12,000 rpm. Modern equipment for dairy production has automated control and protection equipment. Monitoring and control is implemented through a combination of sensors and a controller with an operator operating panel. Having set the desired program, the user starts the separation process with robotic control in accordance with the established milk processing algorithms. Protective systems are mainly represented by devices that prevent electrical and thermal overloads.